Guidelines For Building an REA Accumulator -- Using the Hampton Technologies' Accumulator Control Kit

What is in the Kit?-

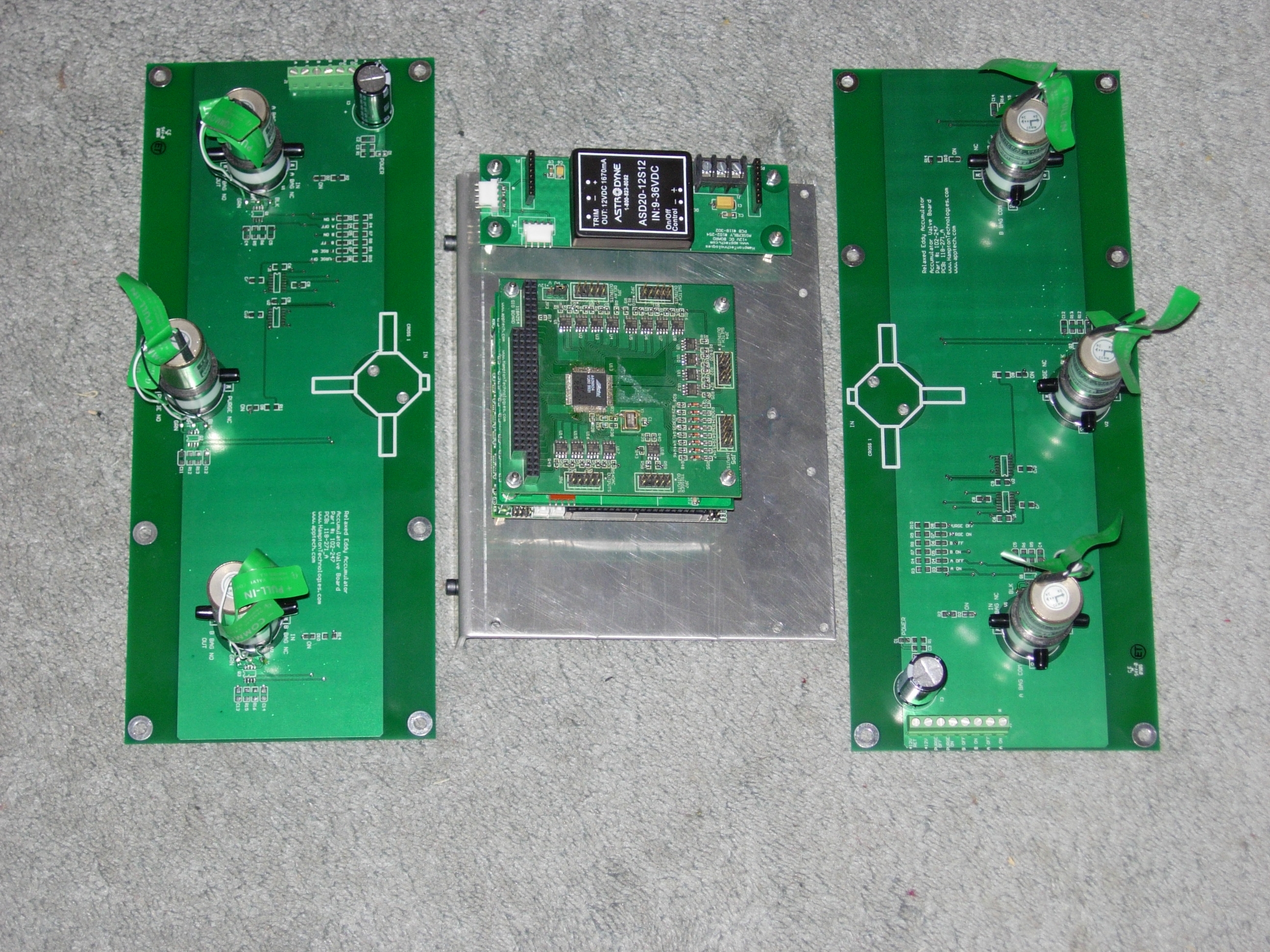

2 - Valve Boards - printed circuit boards with three General

Valve Company (Parker) Iso-latch valves on each and the

electronics switching the current to the valves. One board

manages the UP samples; the other, the DOWN samples.

- size, each about 305 mm (12") x 126 mm (5") x 70 mm (2.75") high

- weight, each about 430 grams (~1 lb)

- standoff mount-4, 5mm (.2") holes-292mm (11.5") x 114mm (4.5") -

1 - MicroController Assembly - several printed circuit boards

mounted on an aluminum bracket. Within the assembly

are the power supplies converting VIN (10-30 VDC) to the

voltages required by the valves and electronics.

- 205mm (8") x 165mm (6.5") x 100mm (4") -- 794g (28 oz.)

- ThruHole mount - two 4mm screws on 152.4mm (6") centers - 1 - 5 meter long power cable bringing VIN to the MicroController

- 1 - 5 meter long data cable able to carry command and status signals between the Accumulator's MicroController and the Supervisor.

- 1 - Wiring diagram showing connections from MicroController to each Valve Board.

- Only UP and DOWN samples are supported.

- Normally, bags are fed using 1/8" OD Teflon tubing and sample gas is transported from the Segregator to the Accumulator using 1/4" OD Teflon tubing. This tubing and its fittings are not included.

- The sample gas outputs of the Segregator are 1/4" SwageLock bulkhead connectors.

- The Iso-latch valves use 1/4" x 28 fittings for 1/8" tubing.

- Wiring cables from MicroController Assembly to each Valve Board. Use 20 awg. color coded wire for ease of assembly. These are 12VDC lines using less than 2 Amps. Eight wires to each board.

- The plumbing, tubing, cross, fittings connecting the sample tubes to the valves and the valves to the accumulation bags. One port on each valve needs to be plugged (1/4 x 28 plugs).

- Usually, the samples are accumulated in Tedlar bags; these are not in the kit. The plumbing connecting to these bags is not supplied.

- A framework to hold the bags, tubing and electronics must be provided by the customer. See our website for example accumulators.

Theory of Operation:

The segregated sample gas (UP and DOWN) is directed to the appropriate valve board "cross." Each of the three cross outputs connect to one of the valves. In normal operation, one of these valves is open the others closed. Two of these valves connect to accumulator bags -- one to the "A" set the other to the "B" set. The third valve does not connect to a bag; it only provides a flow path used to "PURGE" the Segregator, the tubing leading to the Accumulator and the cross. Each valve has a second port normally not used; it is plugged. The bags are connected to the common port. When a bag is being filled, the bag is connected to the sample gas stream. As bags are filled, they are connected to the plug (or equipment analyzing the sample then flushing the bag).

The General Iso-latch valves use very little power because they change states using 50 millisecond pulses. Most of the time they use no power. The MicroController manages delivery of these pulses to the appropriate valve armature at the correct time. The MicroController has a precision clock and communicates with the Supervisor. The Supervisor tells the MicroController which state is next and when the state change should occur.

As a sampling period ends, the MicroController switches the flow to the other bag set and the just filled set is changed. Then, filled sample bags are transported to analytical equipment and replaced with empty bags -- ready for the next change. Automatic systems have been built to pull and analyze sample gas from from filled bags without removal. In this case, the plugged valve ports are connected to the automated analytical subsystem.

Teflon tubing and stainless steel fittings are often used to minimize sample contamination. Due to their low contamination potential, Tedlar, Peak and PPS have also been used.

Optional Possibilities:

The controller running the Accumulator has much more potential management power than used for accumulation. With optional interface boards and software, it has been used to interface and even control analytical sub-systems. It is able to communicate with analyzers and data collectors using RS-232, A-to-D conversion, solid state switches and inputs. Analysis data can be collected and forwarded to the Supervisor for storage or forwarding into the Internet or radio modem. Hampton Technologies can provide hardware and software to your specifications or supply development help for your team.

List of Useful Suppliers:

Popper And Sons -- popperandsons.com -- cannula and fittings for septum injection

Apex Instruments -- apexinst.com -- bags, tubing, fittings

CEL Scientific -- celscientific.com -- bags and misc. supplies

Upchurch Scientific -- upchurch.com -- tubing, fittings and more

Western Analytical -- westernanalytical.com -- tubing, fittings, GC supplies and more

"; while(!feof ($taginfo)) { $line = fgets($taginfo); echo $line; } fclose($taginfo); echo "

"; echo "Last modified: "; echo $today; echo "

"; ?>